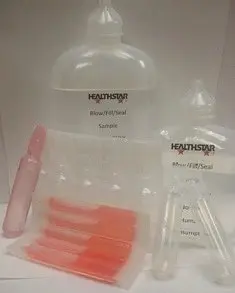

HealthStar, Inc. Unveils Patented Autoinjector with Blow-Fill-Seal (BFS) Carpule Technology

HealthStar, Inc. Unveils Patented Autoinjector with Blow-Fill-Seal (BFS) Carpule Technology

[Braintree, MA], September 8, 2025 — HealthStar, Inc., a leader in innovative Pharma...