Turnkey Sterile Glass Bottle Production Line for IV Fluids. Line Configured as Follows - Washing / Filling / Stoppering / Capping / Terminal Sterilization / Visual Inspection & Semi-Automatic Labeling. Detailed Equipment Descriptions Included in Attached PDF.

Equipment running in production through July 2024. Available for removal mid-August 2024.

Filler/Capper Output: 1,100 - 1,500 Bottles/Hour Depending on Size

Format parts included for 100 ml, 250 ml, & 500 ml glass bottles.

European Voltage

Line consists of:

1. DF Model LF-GV 800/6 Bottle Washer, YOM 2020, complies with good manufacturing standards (GMP) and FDA directives.

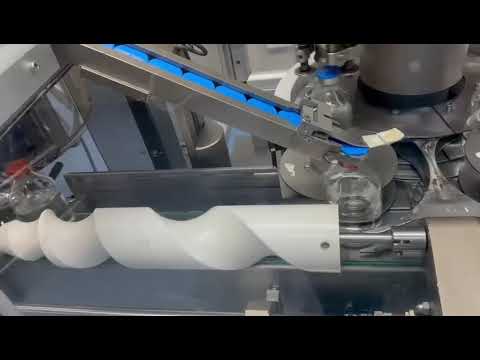

2. MEA Pharma Linear Filling & Rubber Stoppering Machine, YOM 2018, under LAF with in-out conveyor belts, 4-up filling system, fill accuracy: ± 1.5 % at 500ml

3. DF Model GC/4T-R Capper, YOM 2020, continuous movement model with 4 capping heads by rolls

4. Autoclave Sterilization Trolleys - 10 trolleys in SS 316 complete with movable trays, plus 10 under trolleys SS 304 with wheels

5. Fedegari Model FOW6/C Autoclave, YOM 2018, superheated water sterilization autoclave, 2 trolleys double door interlocked, Capacity: 5m3, 100ml= 6412 bottles/cycle, 250ml= 2620 bottles/cycle, 500ml= 1976 bottles/cycle

6. DF Model SSA/5 ETA1000 Visual Inspection & Semi-Automatic Labeling, YOM 2020, checks the vials contents magnified by a video-camera, with selective manual discard, and then applies the label with variable data print

We use cookies to improve your experience. Privacy Policy.